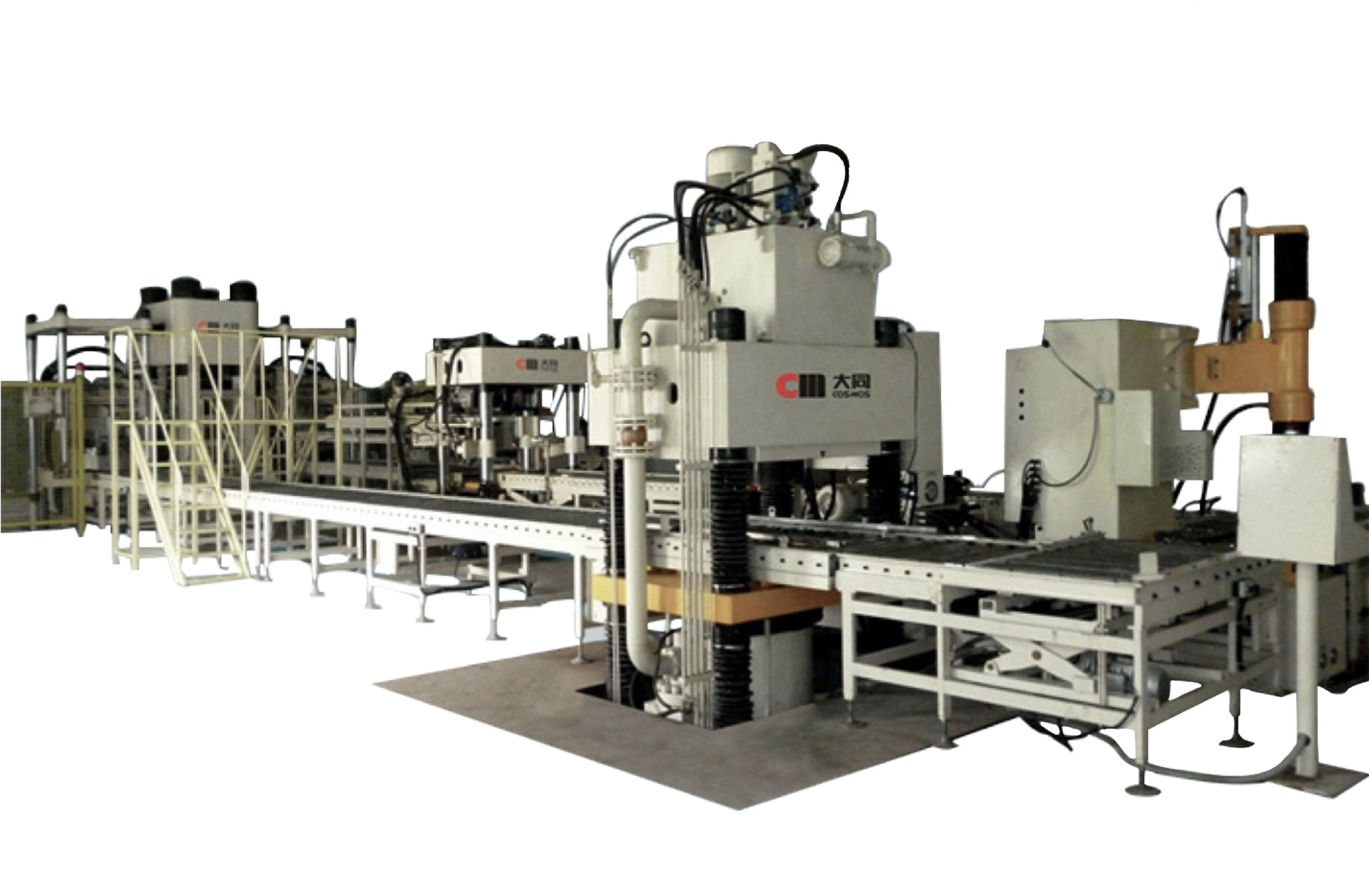

High precision resin grinding wheel automated production line

Product features:

Composition: The automated production line for resin grinding wheels is composed of a filling hydraulic press, a pre pressing hydraulic press, a hot pressing hydraulic press (can be paired with 2 units), a demoulding hydraulic press, a conveying device, a finished product insulation box, a mold cooling device, a mold preheating device, etc.

Precision monitoring: Electronic rulers and pressure sensors are used for position and pressure monitoring to improve pressing accuracy.

Pressure accuracy: The repeated accuracy of the master cylinder pressure reaches ± 3%, which can effectively control the waste generated due to machine tool accuracy issues.

Energy saving effect: The use of servo motor drive can achieve the best energy-saving effect; Energy saving can reach 30-50%.

Silent effect: Using a servo motor drive system, it can meet the requirements of different processes for speed and pressure changes, and the movement is smoother and quieter.

Heating control: The heating system can choose between heating tube mode or oil heating mode, and the temperature of the heating plate can be precisely controlled within ± 4 ° C.