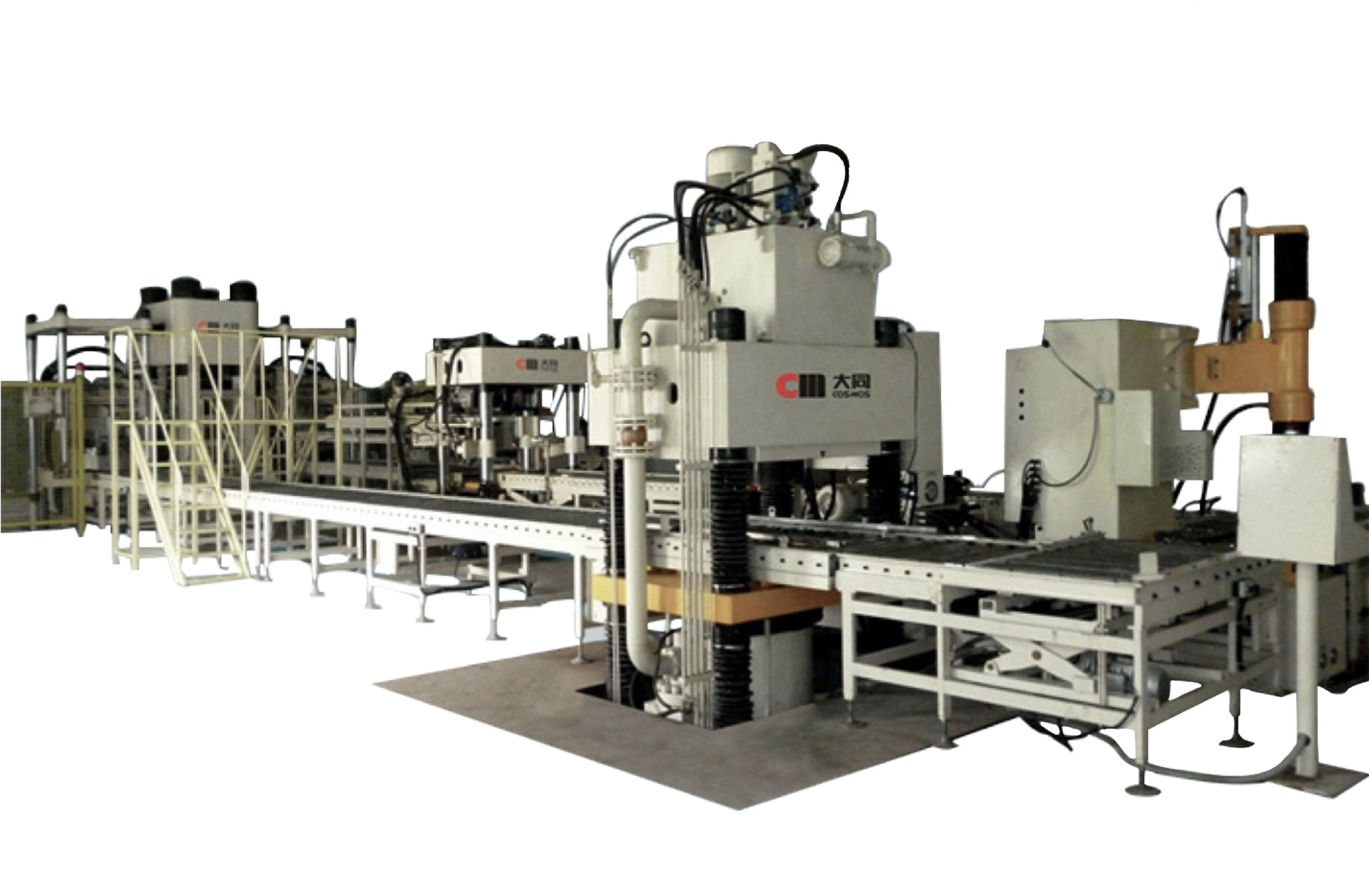

Frame type guide rail servo cold extrusion hydraulic press

Product features:

Precision monitoring: Using grating rulers and pressure sensors for position and pressure monitoring to improve pressing accuracy.

Position accuracy: The repeated accuracy of the master cylinder position reaches ± 0.01mm, which can effectively control the waste generated due to machine tool accuracy issues.

Pressure accuracy: The repeated accuracy of the master cylinder pressure reaches ± 3%, which can effectively control the waste generated due to machine tool accuracy issues.

Energy saving effect: high-power motors meet the process requirements of high speed and high pressure, and the use of servo motors can achieve the best energy-saving effect; Energy saving can reach 30-50%.

Silent effect: Using a servo motor drive system, it can meet the requirements of different processes for speed and pressure changes, and the movement is smoother and quieter.

Master cylinder design: Adopting integral forging and precision grinding, it has high reliability for use under high pressure.

Machine Tool Structure: The bed body is made of high-quality steel plates and welded as a whole. After annealing treatment, finite element analysis is carried out to fully ensure the elastic deformation under the highest pressure. The slider adopts a four corner eight sided guide rail guide design, which has strong shock resistance and anti eccentric load capacity. The whole machine runs stably and is precise and durable.